Many people may have encountered circular protrusions on the street and passed over them. These protrusions are manhole covers that prevent people and vehicles from falling into the empty space beneath. These covers serve as a type of protection for access channels to underground facilities and come in various types. In this article, we will explore the manufacturing methods of manhole covers. Stay with us to become familiar with the different types of these covers and their characteristics.

What is a Manhole Cover?

Typically, underground facilities such as telecommunications, water, sewage, etc., require access and control systems through a space that allows movement. Therefore, a channel is dug from underground to the surface so that if issues arise, access to the facilities can be obtained. These channels are covered with special doors known as manhole covers to prevent damage to vehicles and pedestrians. These covers usually have a diameter of about 60 centimeters and are available in various materials such as composite, cast iron, concrete, etc., depending on their usage. The use of these covers helps manage emergencies during natural disasters and assists in collecting and directing floodwaters to underground channels. Thus, these covers offer numerous benefits and help prevent many risks and damages.

Types of Manhole Covers

The manufacturing method of these covers depends on the type of cover and its material, requiring different raw materials and additives. Therefore, it’s essential to first understand the various types of these covers and their characteristics.

- Concrete Covers: These covers use metal as the framework and concrete combined with polymer fibers as the cover body. This type of cover is heavy and using additives like polymer fibers increases tensile strength and prevents corrosion, cracking, etc.

- Cast Iron Covers: Cast iron covers are more resistant compared to the previous type and maintain their quality over time. However, due to the high cost of cast iron, the production of such covers is expensive, and the risk of theft is also high.

- Composite Covers: These covers are made from compressed plastic, which is very lightweight. Additionally, this compressed plastic has high pressure resistance and durability. Composite covers have recently entered the market but are replacing many traditional cover models due to their advantages.

- Polyethylene Covers: Polyethylene covers are not highly resistant. Therefore, they are not suitable for high-traffic areas. Typically, polyethylene covers are used for water and sewage meter access.

In general, you should consider environmental conditions when choosing a cover and select one with sufficient resistance based on the traffic and vehicle flow in that area.

Manufacturing Methods of Manhole Covers

These covers come in various materials depending on the application and the required strength. Therefore, a wide range of raw materials can be used in their manufacturing. Today, many manufacturers use different production methods for these covers. However, most manufacturers follow the steps below to produce them.

- First, the target market is identified to determine the required raw materials in specific quantities.

- Each chosen product has different physical and appearance specifications that must be calculated for size and details.

- Then, based on the raw materials and calculated specifications, molds are designed using aluminum and wood in shapes like square, rectangular, circular, etc.

- At this stage, the raw materials are melted into an alloy and poured into the designed molds.

- After the materials are fully placed in the molds, they are kept at a specific temperature to allow the molten material to cool and take shape. Once the material dries, it is removed from the mold.

- At this point, to increase the cover’s strength, a compression process is used. In this process, the cover is placed in a sand-filled flask box and compressed by the weight of the sand.

- The cover is now ready. However, before being released to the market, its quality is checked. Therefore, the produced covers are transferred to a laboratory environment and, after evaluation and ensuring they meet standards, are released to the market.

When all the mentioned steps are carried out correctly and with high quality, the produced product will meet the necessary standards for use in various locations.

Types of Manhole Cover Manufacturing Methods

As mentioned earlier, manufacturers use various methods to produce these covers, which are described as follows.

BMC Method

In this method, all the steps mentioned in the previous section are performed. The only difference between the BMC method and other methods is the state of the raw materials when placed in the mold. The raw materials are placed in a paste-like state in the designed mold. Then, reinforcements with lengths of 10 to 15 millimeters are added. Semi-traffic and non-traffic manhole covers are made using this method.

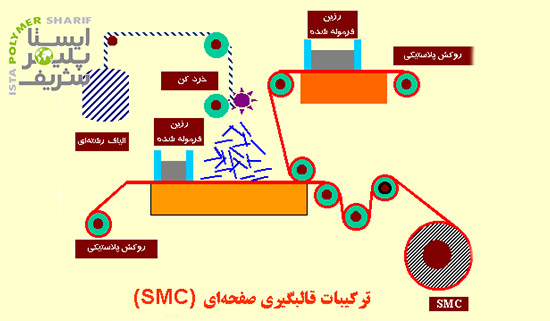

SMC Method

In this method, the raw materials are in sheet form and are placed inside the mold along with reinforcements such as glass and carbon.

Usually, these reinforcements, with lengths of about 30 to 60 millimeters, are baked with the raw materials at a specified temperature and pressure. As a result, the cover has a combination of features from sheet materials and molding. This method is used for producing traffic covers.

FRP Method

In this method, polyester resins, along with reinforcements and other additives like quartz, are distributed in various parts of the mold. These materials are then placed under pressure at a specific temperature and shaped.

Conclusion

Manhole covers are essential equipment for covering manholes and must have high resistance. Today, based on environmental conditions and traffic volume, these covers are available in various shapes and materials. Generally, manhole covers are produced through steps including specification calculation, mold design, molding, cooling, compression, and quality control. In this article, we reviewed all manufacturing methods and the characteristics of various types of manhole covers to help you understand how to choose the appropriate type of this product.