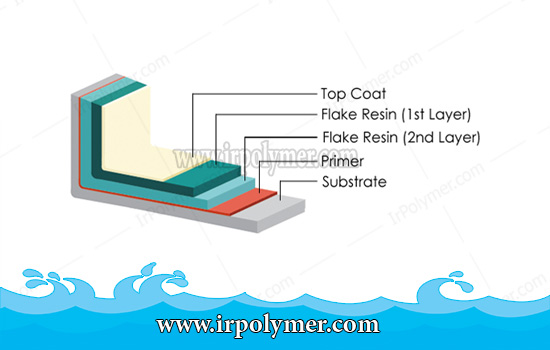

Glass flake lining is a type of lining applied to surfaces using resins resistant to corrosive fluids combined with very thin glass flakes. The presence of these thin glass flakes increases impermeability by extending the fluid’s path through the cross-sectional area of the glass flake lining. This phenomenon occurs even with very thin linings.

The glass within the cross-section of the tank’s glass flake lining significantly limits shrinkage after curing (shrinkage), which enhances better adhesion to the coated surface during hardening and post-curing. These stable properties provide better resistance to cracking and lifting from the surface.

Applications: Acidic environments, seawater, alkaline environments, polar solvents, food industries

Features: Chemical resistance, thermal stability, resistance to corrosion, thermal shock resistance

Advantages of Glass Flake Lining for Tanks

- Good chemical resistance

- Excellent corrosion resistance

- No need for curing

- High operational efficiency

- Heat resistance

- Ease of repairs

- Good mechanical properties and resistance to abrasion

- Strong adhesion to substrates

Another type of tank lining is urethane lining, which due to its special properties and high urethane resistance, is very durable.