A septic tank is an underground chamber, usually buried tank in the ground, where wastewater is stored and treated. In Persian, it is known as a “gand anbar” (literally, “dirty warehouse”). This tank, which can be made from various materials such as metal, polyethylene, and composite, is responsible for primary wastewater treatment. ABtank septic tanks can be manufactured either vertically or horizontally according to customer requirements.

What is a Septic Tank and How Does It Work?

To understand the importance of these waste tanks, we examine the issue of clogged drainage holes. When the amount of wastewater becomes so high that anaerobic bacteria cannot convert solid waste to liquid effluent, drainage holes get clogged. This device is designed to solve this problem. Essentially, it converts the troublesome solid waste from residential complexes, labor camps, industrial complexes, and office buildings into liquid effluent, thus preventing clogging.

This device reduces the pollution load of wastewater by up to 60%. In this process, anaerobic bacteria transform microbial waste through a series of chemical processes into liquid effluent, methane gas, and sulfur dioxide, thereby protecting underground water tables from hazardous wastewater infiltration.

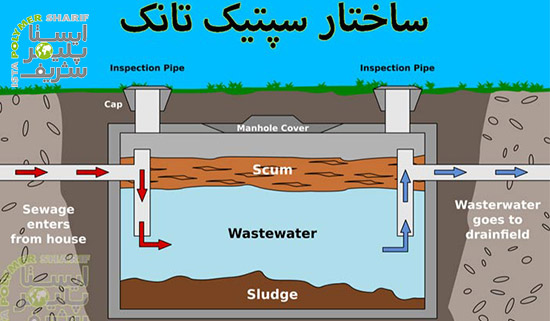

Components of a Septic Tank

-

- Inlet Section: Consists of the inlet pipe and baffle.

- Primary Tank: Comprises half of the device’s body, where solid waste separation occurs.

- Partition Wall: Prevents sludge and floating oils from entering the clarification tank.

- Clarification Tank: Collects floating and settling materials and constitutes one-third of the entire device.

- Ventilation System: Expels gases produced during the anaerobic chemical process, primarily methane.

- Outlet Section: Consists of outlet pipes and a buffer.

- nspection ports: One or more inspection ports on top of the tank allow access to the inside of the septic tank for inspection and, if necessary, for pumping out solid waste.

Types of Septic Tanks

The septic tank has various types, which can be categorized based on the primary material used in their construction. These categories are as follows:

Polyethylene Septic Tank

Lightweight, highly resistant to acid corrosion, and durable against soil pressure due to its double-layer structure. Easy to empty sludge through built-in drainage valves.

Concrete Septic Tank

Pre-manufactured

Coated Metal Septic Tank

Metal tanks, coated to nearly eliminate corrosion from wastewater. Produced by ABtank.

Brick Septic Tank

Constructed using brick and sand-cement mortar.

Composite or Fiberglass Septic Tank

Used in commercial complexes, office buildings, and residential complexes.

Septic Tank Pricing

The price of a septic tank depends on various factors, including the tank body material, the number of tanks, and the number and height of manholes. Due to constant price fluctuations, maintaining fixed prices is challenging, but as a manufacturer, we offer our products at the most reasonable prices.

Applications of Septic Tanks

With industrialization and urbanization, the increase in factories and workshops has led to higher wastewater production. Using equipment like composite septic tanks for wastewater recycling is crucial due to water scarcity. These tanks are used for domestic, industrial, and sanitary wastewater treatment.

Septic tanks are used for:

- In wastewater from restaurants, hotels, and dining halls, there is a significant amount of grease and oil. To prevent the rapid filling of the absorption well and clogging of pipes due to the accumulation and sediment caused by grease, a septic tank can be used to separate grease and other wastewater contaminants. Through wastewater recycling, treated water is more readily available for industrial applications.

- In sanitary sewage systems, the use of a pre-treatment system in residential units, commercial buildings, hotels, and restaurants is mandatory, with septic tanks being used for this purpose.

- Equalization and Pumping: This system is also used for the equalization and pumping of sewage in wastewater treatment systems.

Using Septic Tanks for Poultry Farms

One of the significant applications of septic tanks is their use in poultry farms for treating wastewater, which is a prerequisite set by the Environmental Protection Agency for obtaining a license to establish poultry and cattle farms. To treat wastewater in poultry farms, either a wastewater treatment package or a septic tank can be used, with the wastewater treatment package being more expensive. The treated wastewater from poultry farms can be used for irrigating green spaces. Moreover, using a septic tank eliminates the environmental pollution issues.

The application of septic tanks can vary depending on their construction material, which can be brick, concrete, polymer, or composite (fiberglass).

Importance of Acid Levels in Septic Tank Construction

Depending on the type of incoming wastewater and its components, for example, if it contains a high amount of acid, a septic tank with anti-corrosion properties should be used. Generally, concrete and brick types are prone to permeability and cracking, leading to negative performance and reduced application in many cases. Therefore, polyethylene septic tanks and composite types are more commonly used.

Septic tanks are often used in locations where there is no sewer system and a pre-treatment stage is needed. In fact, when there is no municipal sewage collection network and no municipal wastewater treatment plant, the use of a septic tank becomes essential to prevent environmental pollution and to treat wastewater.

Conclusion

Using septic tanks prevents the hazards of pollutants like sulfates, which can convert to toxic, flammable, and colorless hydrogen sulfide gas under anaerobic conditions. They also help manage methane, nitrate, ammonia, and suffocating nitrogen compounds released in wastewater. Septic systems are crucial in hospitals to manage highly contaminated wastewater efficiently and cost-effectively. For advice on purchasing septic tanks, contact ABtank experts at 02191309063