In collaboration with polymer researchers, we have succeeded in using nanocomposites in the construction of manhole covers, significantly enhancing the strength of these products against pressure and impact. We are proud that by manufacturing composite covers and composite handhole covers, we have been able to reduce the issues of breakage and theft of old cast iron inspection covers in urban areas, thereby preventing the loss of billions of tomans in national assets.

Applications of Composite Covers

- Meter cover

- Telecommunications facility covers

- Sewer inspection rooms

- Underground electrical facilities

- Water facilities

- Oil and gas facilities

- Septic tank covers

- Basin covers

- Aesthetic enhancements

- Firefighting covers

Video introduction of the composite cover

Types of Composite Covers

There are various types of composite covers, which we will get to know below.

SMC Composite Covers

These are covers made of composite materials. With advancements in technology, instead of using the old covers made of cast iron and other materials that could cause issues for organizations and institutions, manhole covers made of composite materials are now used. These are referred to as composite manhole covers.

The composite manhole covers from ABtank are among the company’s polymer products that have quickly gained a strong position in the polymer products market. The production of this type of composite cover in our workshops is 100% automated and uses the SMC (Sheet Molding Compound) process, similar to what you see in SMC tanks.

These composite covers are offered in various shapes and sizes by ABtank, as shown in the table below:

Different Sizes and Shapes of Composite Manhole Covers |

||

|---|---|---|

| Circular Composite Cover | Diameter 60 | View Details |

| Circular Composite Cover | Diameter 80 | View Details |

| Circular Cover | Diameter 32.5 | View Details |

| Square Cover | 50*50 | View Details |

| Rectangular Cover | 80*60 | View Details |

| Rectangular Cover | 70*50 | View Details |

Polymer Concrete Covers

Polymer concrete covers are one of the new products from ABtank that combine the advantages of both concrete and polymer covers. In the construction of these covers, polymer fibers are used within the concrete, which significantly increases the strength of the concrete. These covers are less susceptible to liquid penetration and have higher corrosion resistance compared to traditional concrete. Additionally, the polymer fibers enhance the compressive strength of these covers, making them suitable for long-term use on streets and highways. These covers are also more cost-effective, making them recommended for large-scale projects.

Nano Composite Covers

Due to specialized knowledge and the use of modern science in polymer covers such as nano composite covers and polymer concrete covers, these inspection covers have attracted significant attention from many organizations and companies. They offer the strength of older covers while also providing better elegance and beauty compared to previous models.

These covers also have high corrosion resistance, making them suitable for use in cities with various climates. In areas such as the north and south of the country, where high humidity usually causes severe rusting and corrosion of cast iron inspection covers, composite covers are less affected because they are made with composite fibers that significantly increase weather resistance.

Moreover, their resistance to chemicals makes them suitable for places dealing with chemicals. Air pollution and acid rain also have little impact on these nano composites, preventing corrosion.

Thus, we have started producing nano composite covers for use as water and sewage covers, telecommunications manhole covers, inspection basin lids, and various types of facility covers, which have been well received.

Advantages of Nano Composite Covers

Now, why have nano composite covers been more popular among the various manhole cover options? The main advantages of these products compared to others are:

-

-

- Use of modern technology in these products

- Anti-theft properties of nano composite covers

- Ability to create various color options in these products

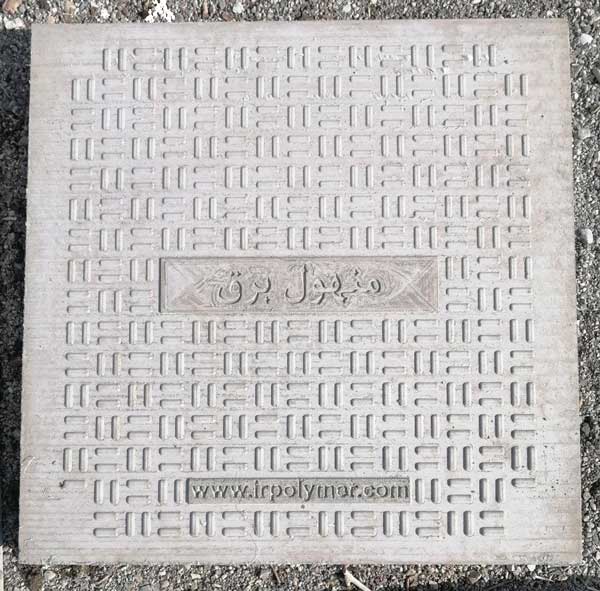

- Option to imprint the company’s logo on the covers

- Competitive pricing compared to other types of covers

- Easy installation of the frame and cover

- High resistance to pressure and traffic loads

- High impact resistance

- High corrosion resistance

- High slip resistance

- Longer lifespan compared to other types of manhole covers

- Significantly lighter weight compared to cast iron covers

- Quick production and delivery time

-

Composite Handhole

Composite Handhole Composite handholes are another type of composite cover that offer high durability.

Anti-Theft Covers

In the past, cast iron covers were commonly used, which due to the high weight of iron, were more expensive. The high price of these products made them attractive targets for thieves. They would remove and steal the cast iron inspection covers, causing damage to municipalities. Additionally, uncovered holes in the city could be very dangerous for pedestrians and vehicles, leading to significant financial and personal injuries.

Today, however, composite covers are used because of their lower weight compared to older models, their more affordable price, and the lack of valuable metals that could be sold, making them less attractive to thieves. These are known as anti-theft covers.

Furthermore, if needed by the customer, special locks and keys can be provided to completely secure the cover, preventing theft and unauthorized access to telecommunications, water and sewage, gas, and other facilities.

Covers for Telecommunications

Manholes have many applications, one of the most important being in the telecommunications industry. These covers are made of polyethylene and have high durability. The covers used in telecommunications must be strong because the related lines often run alongside railways and through difficult areas, requiring the covers to withstand various environmental conditions. There is a high chance of corrosion and wear in these covers, so measures must be taken to prevent this.

Advantages of ABtank Composite Manhole Covers |

||

|---|---|---|

High Strength CoversThese covers are made with nano glass fibers, which provide high strength against the pressure and weight of light and heavy vehicles. |

Low Weight of Manhole CoversDue to the use of nanotechnology, these manhole covers have high strength and durability while being lightweight, weighing less than one-fifth of the cast iron versions. |

|

Easy TransportTheir low weight makes transportation easier. |

No Noise PollutionThese covers do not produce noise when traffic passes over them, unlike cast iron covers. |

|

Corrosion ResistanceThese covers have good resistance to rust and corrosion. |

Weather ResistanceOne of the advantages of these covers is their resistance to sunlight, rain, snow, and other weather conditions. |

|

Anti-TheftWith the installation of locks, these covers cannot be stolen and are not attractive to thieves because they are not made of cast iron. |

Quick Manhole InstallationThe ABtank team manufactures and installs the covers in the shortest possible time. |

|

Custom Logo PrintingWe can engrave any logo you desire on your composite cover. |

Production in Various Sizes and Load ClassesABtank covers can be produced in various sizes and load classes for different weights and pressures, and in large quantities. |

|

Advantages of Using Composite Manhole Covers

Composite covers, due to their composite material, have significant advantages over cast iron and concrete cast iron manhole covers. Some of the benefits of composite covers include:

- High resistance to corrosion

- High mechanical strength against pressure and weather changes

- High resistance to abrasion due to the open environment of use

- Non-stealability

Highly Durable Covers

ABtank composite covers are made from silica, which makes them very strong and durable. Silica is a natural material found in many living organisms and can provide significant strength.

Sunlight Resistant Composite Covers

Sunlight and its strong rays can degrade any living or non-living entity over time, but these composite covers are resistant to sunlight. In this contest, the winner is the composite cover. There might be electrical devices around these ABtank composite covers, raising concerns about electrical hazards. However, there is no need to worry as composite covers are non-conductive.

Advantages of Composite Covers Over Cast Iron Covers

Composite manhole covers are newer than other types of manhole covers and are considered the best due to their composition of materials such as plastic and resin. Mechanically and hydraulically, these ABtank covers are very strong and also very aesthetically pleasing.

Their high resistance to sewage gases is remarkable, and the high quality of these covers can be a compelling reason to choose this type of cover. Manholes are used to access the underground world of pipes, and they allow for the repair of these pipes. Composite covers have many advantages over cast iron covers, some of which include:

Advantages of Composite Covers Over Iron Covers

Composite is lighter than silica, making the transportation of composite covers much easier. These covers cannot be remade and are non-recyclable. It is obvious that a cover not made of iron will not rust. Since these covers are not made of iron, this is a significant advantage for a manhole that is exposed to water for a long time.

Price of Composite Covers

The price of these covers and manholes can vary depending on their size and application. Manual, machine, or a combination of these methods can be used to produce composite manhole covers. Manual production of composite manhole covers is time-consuming, and the final surface quality depends on the operator’s skills. The price of manually produced composite manhole covers is much lower than the finished cost of manholes, depending on the working class (traffic or non-traffic).

The production of composite manhole covers is done using either BMC or SMC raw materials. BMC raw materials are used for producing composite manhole covers for low class and non-traffic applications. SMC raw materials are used for producing high-pressure and traffic-capable manhole covers. The final cost of this product using the SMC method is higher than the cost of composite manhole covers produced using the BMC method. Generally, the price of composite manhole covers is influenced by their working class, diameter, and shape.

Composite Cover Manufacturing

This product was developed in the mid-20th century. The material for this type of cover is cast iron, and it is manufactured by pouring molten iron into special molds and allowing it to cool, resulting in covers ready for installation, each weighing around 135 kilograms.

Manholes are constructed from various components. If the materials used are plastic or polymer, metal, and ceramic reinforced with fiber (glass, carbon, aramid, etc.), it is referred to as FRP. If the fiber used is glass, it is called GRP, or glass-reinforced plastic.

Dimensions of Composite Covers

Composite covers can vary depending on their use and can be made in different sizes. Most of ABtank orders have the following dimensions:

| Sizes and Dimensions of Composite Covers | |||||

| Diameter Length | 26 | 32.5 | 60 | 80 | 100 |

The shapes of composite covers can be circular, oval, square, or rectangular, depending on the type and shape of the manhole.

| Working Classes of Manhole Covers | |||||

| 1.5 tons | 12.5 tons | 25 tons | 40 tons | 60 tons | 90 tons |

Sewer Cover Standards

Due to the importance of quality, performance, and resistance of sewer covers, as well as the protection of individuals’ health and safety, sewer manhole standards, which include important criteria, must be fully and accurately considered during the construction, selection, or procurement of these covers, according to their application and the environment in which they will be used.

Perhaps the first criterion in sewer manhole standards is the material of the manhole. ABtank FRP manhole covers (fiber-reinforced plastic), GRP (glass-reinforced plastic), BMC, SMC, composite, and nano-composite covers are all considered high-quality, resistant materials that are used in many applications. Being waterproof and particularly non-conductive are important characteristics of the material used for sewer covers. Additionally, the material must have weather-resistant properties and high resistance to chemicals and acids that may come into contact with the cover.

Another standard for sewer covers is the attention to the dimensions of the cover. These covers are designed and produced in square, rectangular, and circular shapes. Circular covers usually have a diameter of around 450 millimeters or 600 millimeters. Rectangular and square covers vary in size from 300 x 300 millimeters to 1200 x 1200 millimeters. It is important to note that the dimensions of the cover differ from the overall dimensions of the manhole. The cover is a part of the overall sewer manhole area and will certainly be smaller than the overall dimensions of the manhole.

Another standard for sewer covers is the production standards and classes of composite covers, which indicate the load-bearing capacity of the cover. Sewer manhole covers are installed in various locations and must be chosen with a specific class of construction depending on the weight and amount of traffic passing over the cover daily. The classes A15, B125, C250, D400, E600, and F900 represent the load-bearing capacities of 1.5 tons, 12.5 tons, 25 tons, 40 tons, 60 tons, and 90 tons, respectively.

Purchasing Composite Covers

One of the main issues with manhole covers is breakage and theft. ABtank has addressed the problems of breakage and theft in urban areas by manufacturing composite covers and composite handhole covers. This article aims to guide you in purchasing various types of covers. If you need consultation for purchasing different types of covers, you can contact ABtank experts at +982144787934 and +982144787935.

.