Usually, the presence of grease in water and its entry into the wastewater system causes pipe blockages and numerous problems. Therefore, in hotels, kitchens, restaurants, etc. grease traps are used to capture grease before it enters the sewage system. These devices come in various sizes and materials, allowing you to choose the appropriate type based on their characteristics.

What is a Grease Trap for Wastewater?

A grease trap for wastewater is an essential device for eateries, preventing the costs associated with sewer blockages and system disruptions. Grease traps are available in both small and large sizes for domestic use and larger establishments. They are used to prevent oil from entering the sewer pipes, thereby avoiding clogs and blockages caused by grease accumulation. Thesegrease trapsare installed at the wastewater outlet and before the septic tank. Various types are available on the market, allowing you to choose one that suits your needs.

Grease Trap for Wastewater and the Application of the DAF Method for Removing Grease in the Food and Dairy Industries, Edible Oil Production, Oil Refineries and Petroleum Products, Textiles and Paper, Restaurant Grease Removal, Animal Factories, Confectionery Industries, Industrial Kitchen Grease Removal, and Dining Halls using Composite Septic Tanks and grease traps.

Types of Grease Traps Based on Material

As mentioned earlier, these devices come in various materials, sizes, shapes, etc., and we should choose the appropriate type based on the placement location and existing conditions. The types based on material include:

Concrete

This type of grease trap is made using Type 5 or sulfate-resistant cement, which increases its durability, giving it a lifespan of 5 to 10 years. The interior and exterior of this device are insulated with waterproofing to ensure higher quality. However, it lacks sufficient resistance to acids and can corrode. Additionally, installation and cleaning are challenging.

Fiberglass

Fiberglass grease traps come in various models such as cylindrical, horizontal, rectangular, vertical, etc. The cylindrical model is particularly space-efficient due to the lack of sharp corners and is easier to install. This type of grease trap is lightweight and highly durable. Due to the fiberglass material, it is both grease-repellent and hydrophilic, and it does not corrode. It can withstand high temperatures and has a long lifespan. One disadvantage of this type of grease trap is its hard material, which can complicate the installation of fittings and may lead to leaks if improperly installed.

Polyethylene

This device is a suitable option for high-traffic areas and can be buried without the need for a retaining structure. The body of this grease trap is usually made from corrugated or spiral-wound pipes, with the spiral model being double-walled. Polyethylene grease traps are produced in high capacities, and you can purchase sizes ranging from 3 cubic meters to 100 cubic meters. One of the advantages of this type of grease trap is its affinity for grease, which can cause grease to stick to the walls and diminish its effectiveness; this issue can be mitigated by using thermal insulation in its body.

Stainless Steel

A stainless steel grease trap has a long lifespan, typically between 10 to 15 years, due to its high-quality, rust-resistant material. However, its high cost often leads consumers to opt for cheaper alternatives. The advantages and disadvantages of this type of grease trap include:

-

- Eliminates bad odors

- Resistant to corrosion and rust

- High-temperature resistance

- Requires careful cleaning to avoid scratches

- Heavy weight

Composite

This device is made of high-density polyethylene, which is highly resistant to chemicals and does not corrode. Due to its very long service life, sometimes up to 50 years, it has gained the attention of many consumers. This type of wastewater grease trap can remove up to 95% of the grease from the effluent and prevent bacterial growth. The lid of this device seals tightly to prevent bad odors from escaping. The installation of a composite grease trap is easy and requires no maintenance.

Types of Grease Traps Based on Usage

Gravity-Based

These grease traps are usually made from stainless steel, fiberglass, or concrete and have high capacities. Gravity-based grease traps are serviced by specialists and perform very well. Typically, this type of wastewater grease trap is used for restaurants, dining halls, kitchens, and similar establishments.

Manual and Automatic

Manual and automatic grease traps differ in their cleaning methods, but both are produced in various sizes for different facilities. The manual type is generally used for smaller locations due to its lower cost. The automatic type heats the effluent according to a pre-set program to separate the grease. To increase the efficiency of an automatic grease trap, a flow equalizer can be used to direct the wastewater into the device.

Types of Grease Traps Based on Location of Use

Restaurant Grease Trap (Under-Sink)

Under-sink grease traps, as the name suggests, are installed beneath the sink, making them a suitable option for locations with limited space. These grease traps are favored by many food preparation centers due to their easy installation and high efficiency, and they are more cost-effective than other models. Each of these models is typically produced in sizes ranging from large to small, allowing for easy installation in the desired location. A restaurant grease trap prevents grease, oil, and fats from entering the wastewater lines, thereby avoiding blockages and protecting water sources. This device is usually placed in the kitchen, near the sink, or by the dishwasher.

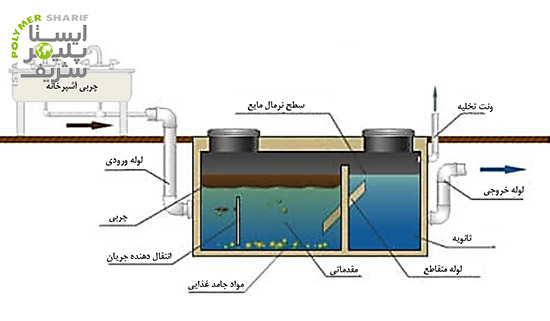

This device has two chambers and works in a way that allows the grease to cool at room temperature. As it cools, the grease solidifies and floats to the top of the device. Water flows from the bottom of the first chamber to the second chamber through pipes, while the grease remains on the surface.

Grease Removal Methods

A grease trap for wastewater is responsible for separating grease and oil from the wastewater. There are multiple methods for grease removal. Low-density liquid fluids in water are a type of pollution in wastewater known as oil. Oil is the non-aqueous phase, and water is the aqueous phase. Oils are treated in grease traps either by flotation or by using polar and non-polar methods.

Several methods for grease removal include:

- API

- CPI

- DAF

- DNF

- DOF

- Electroflotation

The most common method is DAF.

DAF Grease Removal Method

The DAF method is more well-known than other methods for grease removal. The process of removing grease and treating wastewater with this method involves several steps:

- Before treatment and entry into the grease trap, large and suspended particles in the wastewater, such as plastics, are separated by a coarse manual screen. This step increases the efficiency of the package in the treatment process and makes grease removal better and easier.

- Air and coagulants are added in the inlet wastewater path to the pump, or in other words, in the suction part of the pump. After passing through the pump, the coagulants and air mix with the wastewater, increasing the flow pressure. The mixture then enters a closed chamber to become homogeneous. The retention time in this stage is 1 minute, and the pressure exceeds atmospheric pressure, between 2 to 3 atmospheres. The coagulants help particles bind together, increasing their size and ascent speed.

- In this stage, after mixing with coagulants, the wastewater enters a flotation basin. This basin is in open air, causing air bubbles to form quickly, and solid and liquid particles move to the surface of the basin through various mechanisms.

Advantages and Features of the DAF Method

- High efficiency and performance in removing suspended particles, oil, and grease

- Cost-effective and economical compared to biological grease and oil removal methods

- Requires less space

- Does not impose additional pollution load on the biological unit

- Process is not sensitive to the presence of toxic compounds

- Easy access to all necessary equipment

- Requires less retention time

- Low construction cost

- Effective separation of light and settleable materials

- Easy collection due to higher concentration of floated materials compared to settled materials

- Reduces unpleasant odor production

- TSS and BOD removal efficiency reported as 50-90% and 60-85% respectively by flotation

Function of a Grease Trap for Wastewater

A grease trap for wastewater uses the lower density of oil compared to water to capture grease through the grease trap, separating it from the effluent. The cleaned effluent, free of grease, then enters the sewage system. The separated grease from the effluent surface enters a chamber for periodic removal and disposal. This device, placed in the sewage system, traps oil, allowing the effluent to be easily absorbed into the septic system. Solid waste and grease are separated from the liquid wastewater, ensuring the wastewater flows through the network without sediment buildup.

Applications of Grease Trap for Wastewater

The diverse range of these devices, along with their features, allows them to be used in various locations to prevent sediment buildup in sewage pipes. These locations include:

- Kitchen

- Restaurant

- Hotel

- Coffee Shop

- Food Court

- Banquet Hall

- School

- University

- Car Wash

- Carpet Cleaning Facility

- Food Production Workshop

- Bakery

- Confectionery

- Dining Hall

In general, all centers with effluent containing oil and sediment-forming solid particles can use these wastewater degreasers.

Summary

As we have reviewed, grease traps come in various models so that consumers can choose the required type based on their existing conditions. When selecting a wastewater grease trap, you should consider the features of each model and your budget, and consult specialists and sales advisors to choose the appropriate one. If you intend to purchase various grease traps or other products, you can contact ABtank experts for price inquiries, orders, or consultations at +982144787934 and +982144787935.