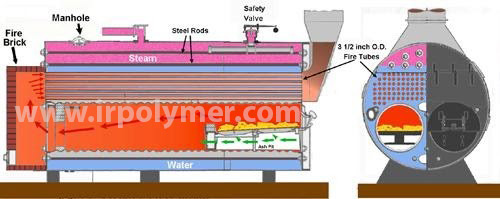

Steam boilers in Iran are produced either according to National Standard 4231 or without third-party supervision. One of the most important methods of testing boilers is on-site inspection, which is conducted through manholes. The manhole cover of a steam boiler should be designed in such a way that opening and closing it remains easy without compromising its strength.

Application of Steam Boiler Manhole Covers

The steam boiler manhole cover is designed to allow technicians and workers to access the boiler for the following purposes based on the device’s size and heat transfer through fire and steam:

- Preparation, testing, and initial setup

- Periodic servicing of instruments, calibrating valves, servicing and renewing water softeners, and related services for fire-tube pipes, etc.

- Inspection in case of necessity

- Steam boilers are made from steel plates. Depending on the type of boiler, one or two manholes are installed. In cases where two manhole covers are required, one is located next to the water drum and one next to the steam drum.

The schematic image shows the location of the manhole and its dimensions and shape.

Material of Steam Boiler Manhole Covers

The steam boiler manhole cover is made of gray cast iron and produced using sand casting methods. According to third-party supervision standards in Iran, it must be made of steel. The importance of a proper fit when closed, resistance to internal pressure, and resistance to corrosion are crucial for this type of composite manhole cover. Continuous exposure to steam and heat increases the likelihood of corrosion and rust, necessitating cleaning or replacement of the cover. Special gaskets are used for a proper fit.

A sample design of a sturdy yet simple steam boiler manhole cover (front view)

Types and Shapes of Steam Boiler Manhole Covers

According to searches, only metal types of this manhole cover are available. The internal ring design should also be considered. The number and size of openings should be such that a person can easily remove and pass through the cover. In heavy industries, steel plates, welding, and hot galvanizing are used for manhole covers similar to boilers. (Sanctions impact the production process.)

A sample of manhole covers for boilers

Geometric shapes like rectangles and squares are not used for covers. Shapes like circles or ovals are more suitable. In these shapes, sensitive points can be aligned along the lines that bear the most pressure, depending on the boiler shell thickness and the manhole location.